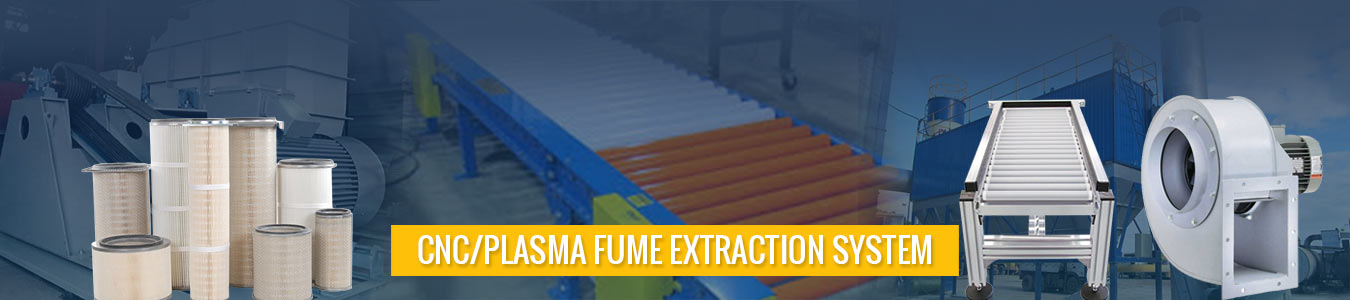

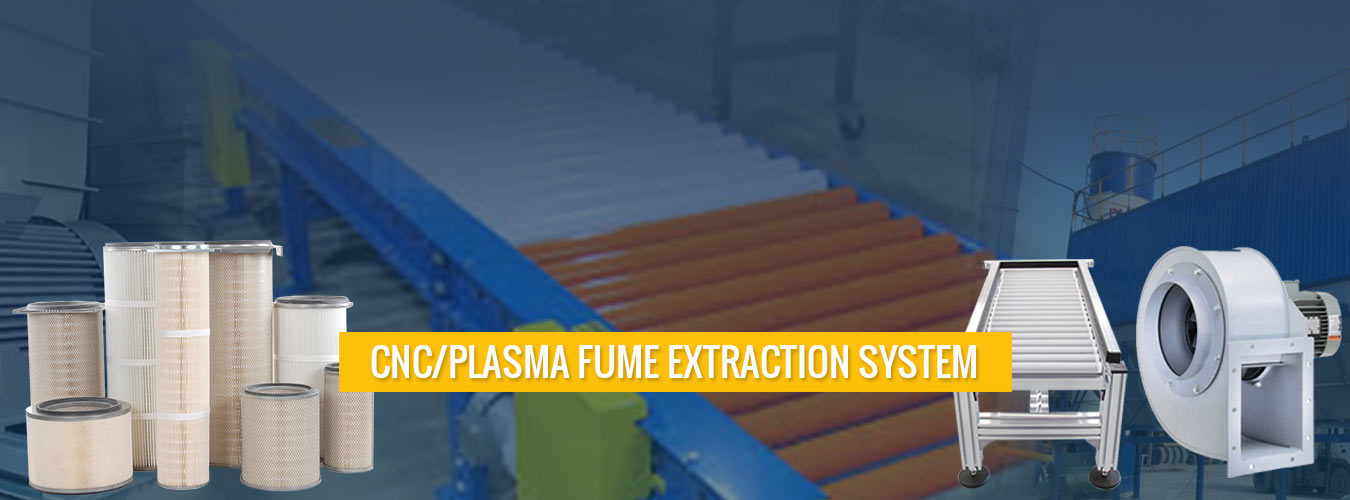

CNC/Plasma Fume Extraction System

Fume extraction system designed for various sizes of cutting table and types of cutting nozzle . Can be supplied along with the cutting table , suction duct and the extraction system or separately

A CNC (Computer Numerical Control) machine is a device that uses computerized controls and programming to operate machinery and tools for various manufacturing processes. CNC machines are widely used in industries such as metalworking, woodworking, plastic fabrication, and more. A plasma fume extraction system is a critical component in CNC machines that utilize plasma cutting technology. Let’s break down both concepts:

CNC (Computer Numerical Control) Machine:

A CNC machine is an automated manufacturing tool that follows a set of programmed instructions to perform precise and repetitive tasks. These machines are controlled by a computer that reads and executes instructions from a numerical code, such as G-code. CNC machines can perform various tasks, including cutting, drilling, milling, and shaping materials with a high degree of accuracy.

The main components of a CNC machine include:

-

- Computer Control Unit (CCU): This is the computer or controller that reads and interprets the G-code instructions.

- Motors and Drives: These components move the machine’s axes (X, Y, Z) according to the programmed instructions.

- Cutting Tool or Spindle: This is the tool that performs the actual machining operation, such as cutting, drilling, or milling.

- Worktable: The surface on which the material is fixed and where the machining operations take place.

Plasma Fume Extraction System:

Plasma cutting is a process that uses a high-temperature, ionized gas (plasma) to melt through metal or other conductive materials. This process generates intense heat and produces fumes, which can include harmful substances and fine particulate matter. To ensure the safety of operators and maintain a clean working environment, a plasma fume extraction system is necessary.

A plasma fume extraction system typically includes:

- Fume Extraction Hood: This is positioned near the cutting area to capture and direct the fumes away from the workpiece and the operator.

- Ducting: A network of ducts carries the captured fumes from the hood to the extraction unit.

- Extraction Unit: This includes a fan or blower that creates suction to draw the fumes through the ducting and filter system.

- Filter System: The fumes are passed through filters to remove particulate matter and potentially harmful substances before releasing the filtered air back into the environment.

Benefits of a plasma fume extraction system:

-

- Protects Operator Health: Prevents operators from inhaling harmful fumes and particulates.

- Maintains Clean Environment: Keeps the workspace clean by removing debris and smoke.

- Compliance with Regulations: Helps companies adhere to safety and environmental regulations related to air quality and workplace safety.